Blown Castor Oil

Blown Castor Oil Specification

- Refined Type

- Refined

- Application

- Paint, Ink, Lubricant, Emulsifier, Plasticizer

- Grade

- Industrial Grade

- Raw Material

- Castor Seeds

- Packaging Size

- 200 Kg Drum / Bulk

- Usage

- Industrial, Lubricant, Additive

- Shelf Life

- 24 Months

- Product Type

- Vegetable Oil

- Type

- Blown (Oxidized) Castor Oil

- Processing Type

- Blown/Oxidized

- Use

- Plasticizer, Paint, Polymer, Soap

- Purity(%)

- 99%

- Iodine Value

- 75-85 (g I2/100g)

- Hydroxyl Value

- 155 - 168 mg KOH/g

- Moisture

- <0.2%

- Insoluble Impurities

- <0.1%

- Acid Value

- <2.5 mg KOH/g

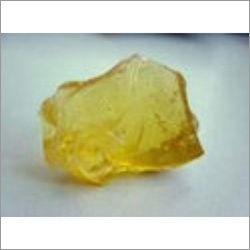

- Appearance

- Clear, Viscous Liquid

- Saponification Value

- 175 185 mg KOH/g

About Blown Castor Oil

Blown Castor Oil is prepared by blowing air or oxygen into it at temperatures different temperatures, with or without catalyst to obtain oils of varying viscosity. It is potential replacement for phthalates and is mainly used as a plasticizer for lacquers, inks, hydraulic fluids, adhesives and leathers. Moreover, this oil is widely used as plasticizer in various industrial applications. Used as a plasticizer in paint, varnish, printing ink and sealant this Blown Castor Oil is non-drying in nature.

Exceptional Industrial Performance

Blown Castor Oil stands out in the industrial sector due to its refined quality and consistency, delivering reliable performance in applications such as paints, inks, lubricants, and polymers. Its high purity ensures stability and efficiency as a plasticizer and additive, catering to manufacturers exacting standards and process requirements.

Storage and Longevity

Retaining quality is crucial for Blown Castor Oil, which boasts a shelf life of up to 24 months when stored in cool, dry conditions inside tightly sealed containers. Proper storage prevents moisture absorption and preserves both the chemical properties and physical appearance of the oil, ensuring uninterrupted industrial use.

FAQs of Blown Castor Oil:

Q: How is Blown Castor Oil processed and what distinguishes its blown (oxidized) type?

A: Blown Castor Oil is produced by passing air through castor oil at controlled temperatures, which oxidizes and increases its viscosity and film-forming properties. This blown (oxidized) process differentiates it from regular castor oil, making it more suitable for industrial applications such as paints and lubricants.Q: What benefits does Blown Castor Oil offer for industrial applications like paint, ink, and plasticizer?

A: The oils high viscosity, excellent solubility in organic solvents, and superior plasticizing properties improve product durability, flexibility, and texture. It enhances film-forming in paints, stabilizes polymers, and serves as an effective emulsifier in inks and other formulations.Q: When should Blown Castor Oil be used within a manufacturing process?

A: Blown Castor Oil is typically incorporated during mixing and blending stages to impart lubrication, plasticizing, and binding characteristics. Its usage is tailored based on the required texture, gloss, and flow properties of the final product.Q: Where can Blown Castor Oil be stored to ensure its longevity?

A: For optimal shelf life, store Blown Castor Oil in a cool, dry place, away from direct sunlight and moisture, inside tightly sealed containers. Proper storage prevents the oil from absorbing water or degrading in quality over time.Q: What are the typical physical and chemical characteristics of Blown Castor Oil?

A: Blown Castor Oil is a clear, viscous liquid with a density of 0.9600.970 g/cm and viscosity of 8001000 cSt at 25C. It features a Gardner color rating of less than 8, a slight characteristic odor, and is insoluble in water but soluble in alcohol and most organic solvents.Q: How is Blown Castor Oil packaged for export and bulk supply?

A: The oil is commonly offered in 200 kg drums or in bulk packaging, ensuring ease of transport, safe handling, and suitability for large-volume industrial clients. Suppliers in India facilitate shipment to global destinations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Castor Oil BP Category

Dehydrated Castor Oil

Iodine Value : 125135

Insoluble Impurities : <0.02%

Grade : Industrial Grade

Saponification Value : 179190 mg KOH/g

Product Type : Dehydrated Castor Oil

Acid Value : 26 mg KOH/g

Castor Oil BP 98 Pharmaceutical Grade

Iodine Value : 83 88

Insoluble Impurities : Negligible

Grade : BP 98 Pharmaceutical Grade

Saponification Value : 176 187 mg KOH/g

Product Type : Pure Castor Oil

Acid Value : 2.0 max (mg KOH/g)